Lamination and Die Cutting

Overlaminates not only increase the durability of your graphics and decals, but also provide ease of application, UV ink protection, and the ability to add gloss or matte textures. After lamination, our steel rule die cutters create your perfect part, every time.

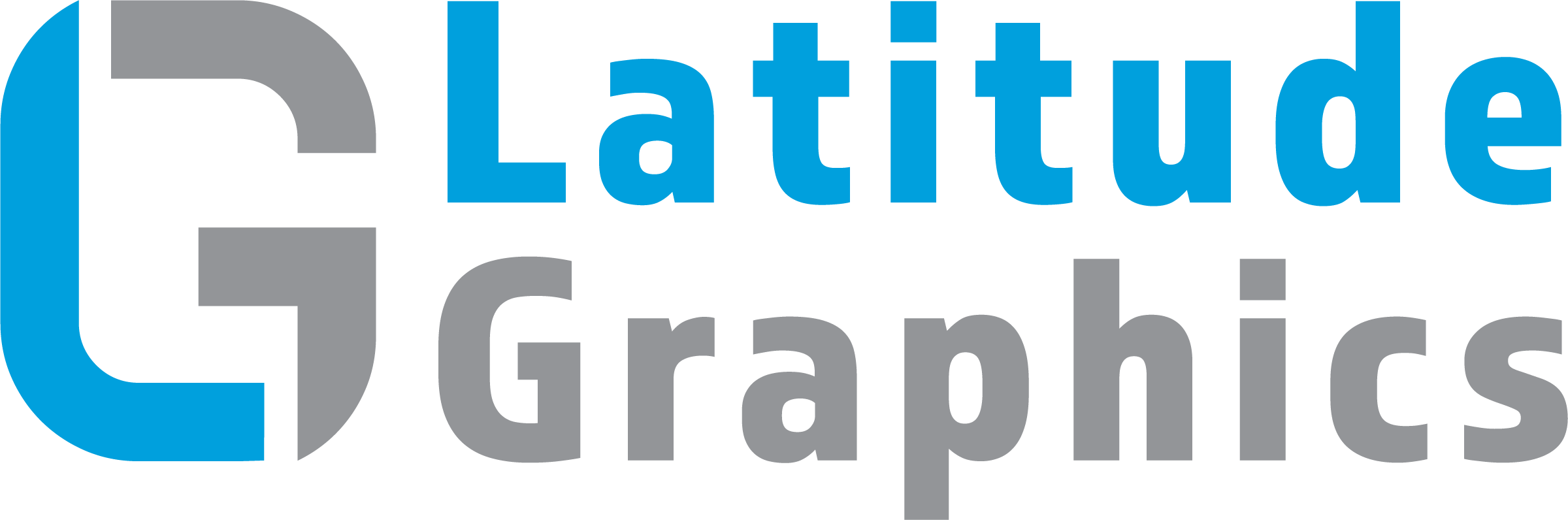

Die Cutting

Cutting dies are thin, razor-sharp steel blades that have been formed into a specific shape or pattern. These are placed into a machine that compresses into the materials, cutting out the desired shape. It allows for multiple pieces of the same shape to be cut in an efficient and uniform way. Capabilities include traditional thru-cut, kiss-cut, and embossed parts.

Dies are durable and can be used over and over.

Want to see our work?

Select a link below to see product samples.

Point of Purchase

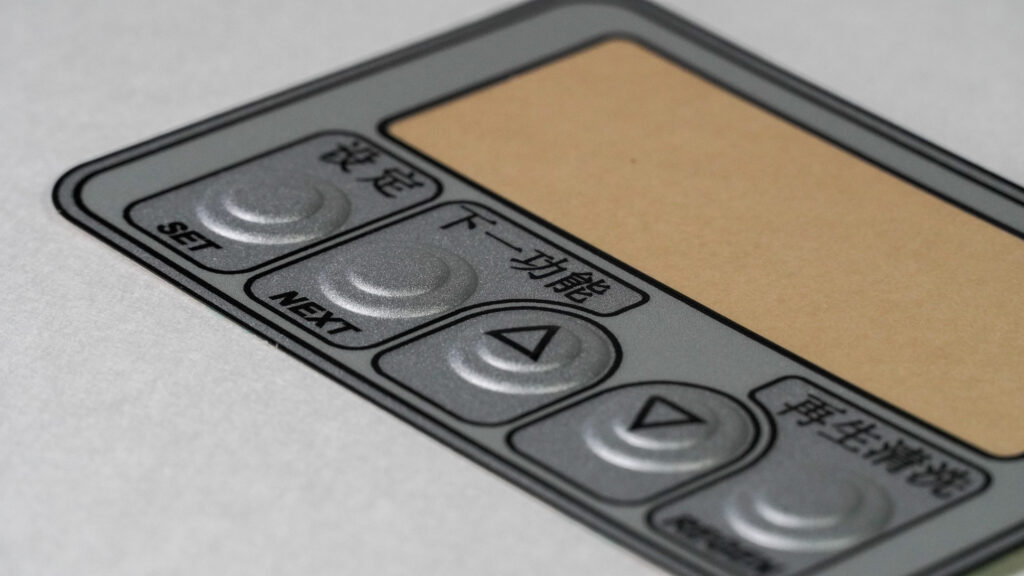

Industrial Overlays

Medical Interfaces

Promotional Signage