Industrial Screen Printing

We have a variety of presses to handle different sizes of materials that are operated by experienced printers. We also have the ability to print on unique materials such as wood, plastic, and metal.

Latitude offers three main methods of industrial screening.

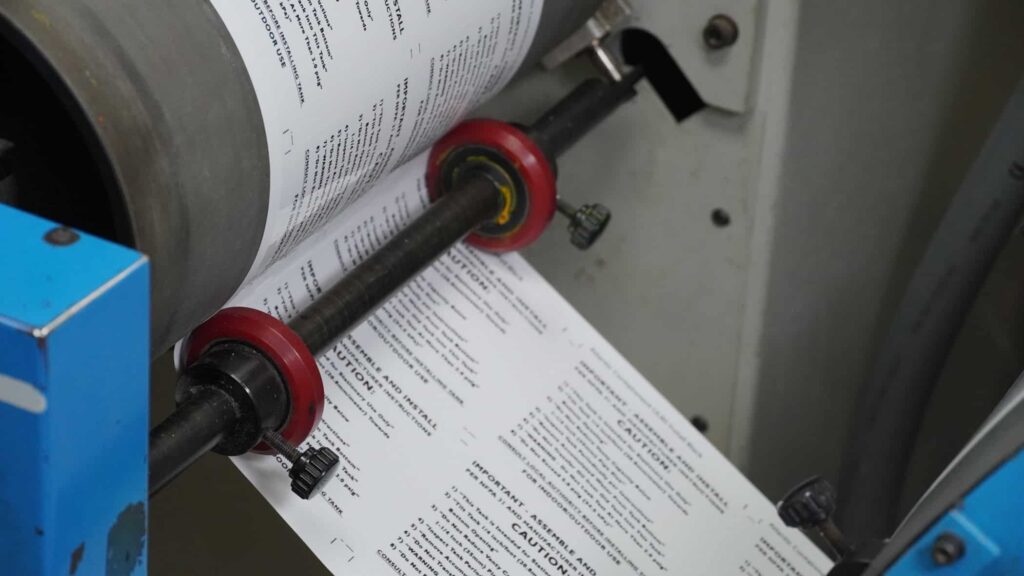

Traditional Screen Printing

Mesh screens are used to transfer ink onto a substrate by pressing the ink through using a squeegee. We have a state-of-the-art exposure unit that produces screens with very fine detail. The screen-printing process allows us to produce high volume runs in a short time frame. The inks create bright colors and exceptional durability.

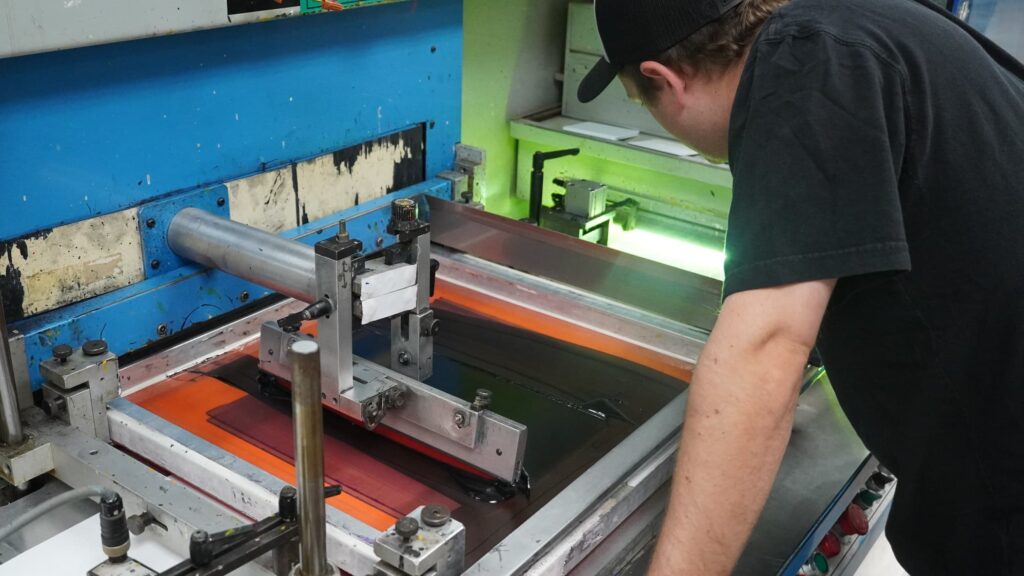

Custom Surface Printing

We have the ability to print on a number of unique surfaces including metal, wood, plastic, and leather. Specific inks are mixed to adhere to these surfaces and hold up over time. Our printers are trained to deal with a variety of unique shapes and textures in order to achieve a clean looking print on your product.

Want to see our work?

Select a link below to see product samples.

Point of Purchase

Industrial Overlays

Medical Interfaces

Promotional Signage